TC3

Machine data

| Item | Standard | With press device | |

|---|---|---|---|

| Machine dimension | 5900 x 4100 x H 3200 mm* / 19.36’ x 13.45’ x H 10.50‘ * | 5900 x 4100 x H 4460 mm* / 19.36’ x 13.45’ x H 14.63‘ * | |

| Useful production dimension | 4000 x 1850 x H 1100 mm / 13,12' x 6,07' x H 3,61' | ||

| Hopper loading height | 2360 mm / 7,74‘ * | ||

| Mixer capacity requirement | 1,5-2 m3 / 2-2,6 yd3 | ||

| Rated power | 15 Kw | ||

| Installed vibration | Electronic, with inverter | ||

| Production cycle average time | 3 / 6 minutes | ||

| Machine weight | 14500 Kg / 31967 lb | 16500 Kg / 36376 lb | |

Products

max external dimensions

Without knock-out or side open system

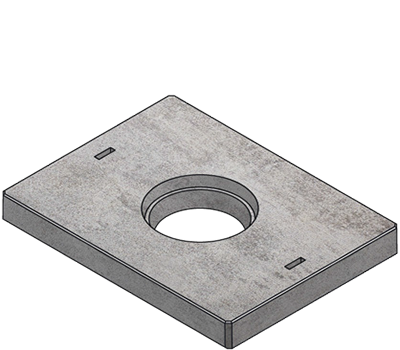

Rectangular slab

4000 x 1800 H 300 mm

13,12′ x 5,91′ H 11,81″

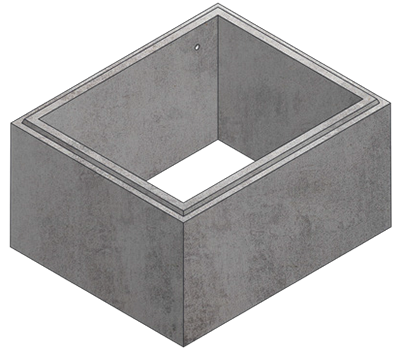

Square manhole

1800 x 1800 H 1100 mm

5,91′ x 5,91′ H 3,61′

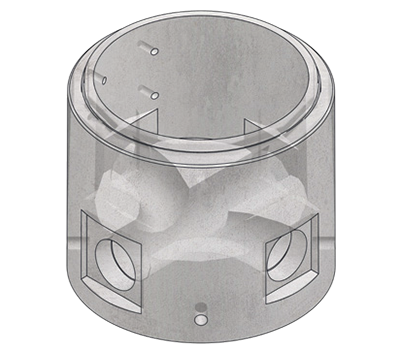

Round manhole

Ø 1800 H 1000 mm

Ø 5,91′ H 3,28′

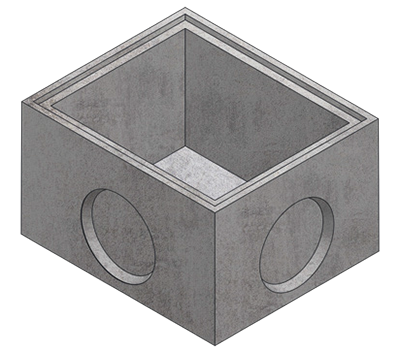

Rectangular manhole

TC2 moulds

With knock-out or side open system

Round slab

Ø 1800 H 300 mm

Ø 5,91′ H 11,81″

Square manhole

1800 x 1800 H 1100 mm

5,91′ x 5,91′ H 3,61″

(3 knock-out)

Round manhole

Ø 1600 H 1000 mm / 5,25’ H 3,28″(manual-knock out)

Ø 1300 H 1000 mm / 4,27’ H 3,28″ (hydraulic -knock out)

Rectangular box culvert

TC2 moulds

What is it

- Semi-Automated mobile vibrating machine to produce concrete elements

- The machine is highly productive, reliable, versatile, fast and easy to use

- The machine is suitable to produce any type of infrastructural product and special shapes in the limit of dimension and weight based on the machine size.

A smart choice

- Highly productive with cycle from 2 to 10 minutes depending on the dimension and the reinforcement implemented in the product

- Eliminate the majority of the civile angineer requested by other technologies

- Minimize the cost of cement

- Minimize the cost of labor. One machine operator, two logistic operators

- One machine, infinite opportunities. Imagination is the limit of what can be produced.

- High quality products with average strength of 55 MPa (9000 psi), 0 water absorption, 0 alteration in freeze thaw test with 3% of saline solution

- Diversify become easy. In 30 minutes you can move from one production to another

- Simple and easy to use

- Simple maintenance

Imagination is the limit

of what can be produced

1 machine, infinite variety of products

Laboratory test

Sophisticated frame

- Heavy welded frame with reinforcement based on structural stressed point.

- The frame have been tested with a special engineering software to identify the structural weaknesses and its limits and frame have been applied to avoid breakage.

Certifications

of each our machines

Production area

| 1 | BATCHING PLANT | Moisture Automation control Aggregate weighing system Planetary mixer |

|---|---|---|

| 2 | PLANETARY MIXER SUGGESTED CAPACITY | 1/1,5 m³ / 1,30/1,96 yd³ |

| 3 | FORKLIFT | Minimum capacity 3.000 kg |

| 4 | FLAT CONCRETE FLOOR | 15/20 cm of thk. / 5.90” / 7.87” of thk. No bumps No obstacles No slopes |

| 5 | WORKSHOP TOOLS | Welder Grinder Shovel Broom Trowel |

| 6 | ELECTRIC POWER SUPPLY | 15 kw |

| 7 | WATER BLASTING | For the daily washing procedure after production |

Suggested Production Covered Area 50m x 45m / 164′ x 147′